Featured method of the first year:

CVD Gas and Precursor Delivery for 2D thin film deposition

Featured success of the first year:

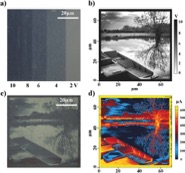

Highest resolution display with

pixels approaching 50 nm

Featured equipment of the first year:

Woollam RC2 spectroscopic ellipsometer

Research Themes

Overall Aim

To accelerate the development of wearable and flexible technologies by integrating device components using advanced functional materials along with scalable, cost-effective and reliable manufacturing techniques.

Scope

Metrology

Flexible and Functional Components:

Flexible Displays

Sensors

Thermoelectric Energy Harvesting

Organic Photovoltaic Energy Harvesting

Modelling

Design for Manufacturing

Scale-up via Roll-to-Roll Manufacturing

Goals

1. To develop scalable roll-to-roll technologies suitable for cost-effective deposition of functional phase-change, photovoltaic, organic sensor and thermoelectric materials.

2. To minimize waste in the deposition of thin-films in case of expensive or environmentally sensitive elements used in functional materials.

3. To develop new approaches for effective in-situ monitoring of key film parameters, in particular film thickness, to guarantee designed-for functional material properties at the manufacturing stage.

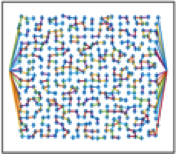

Featured method of the second year:

Modelling to optimise devices

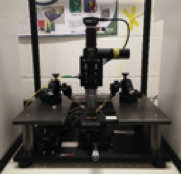

Featured equipment of the second year:

Probe station to measure both electrical and optical characteristics of devices

Featured success of the second year:

Interdigitated electrode gas sensor

WAFT PROJECT

May 2015 - April 2020